From postcards to video calls, the world has moved on to newer, faster and easier forms of communication in a matter of a few decades. This progress has been made due to the proliferation of optical fibre cable (OFC) networks around the globe. But many miss the fact that India is already the world’s third-largest exporter of OFCs, with exports witnessing double-digit growth over the last few years.

BY ANISHAA KUMAR | September 2017 Issue | The Dollar Business

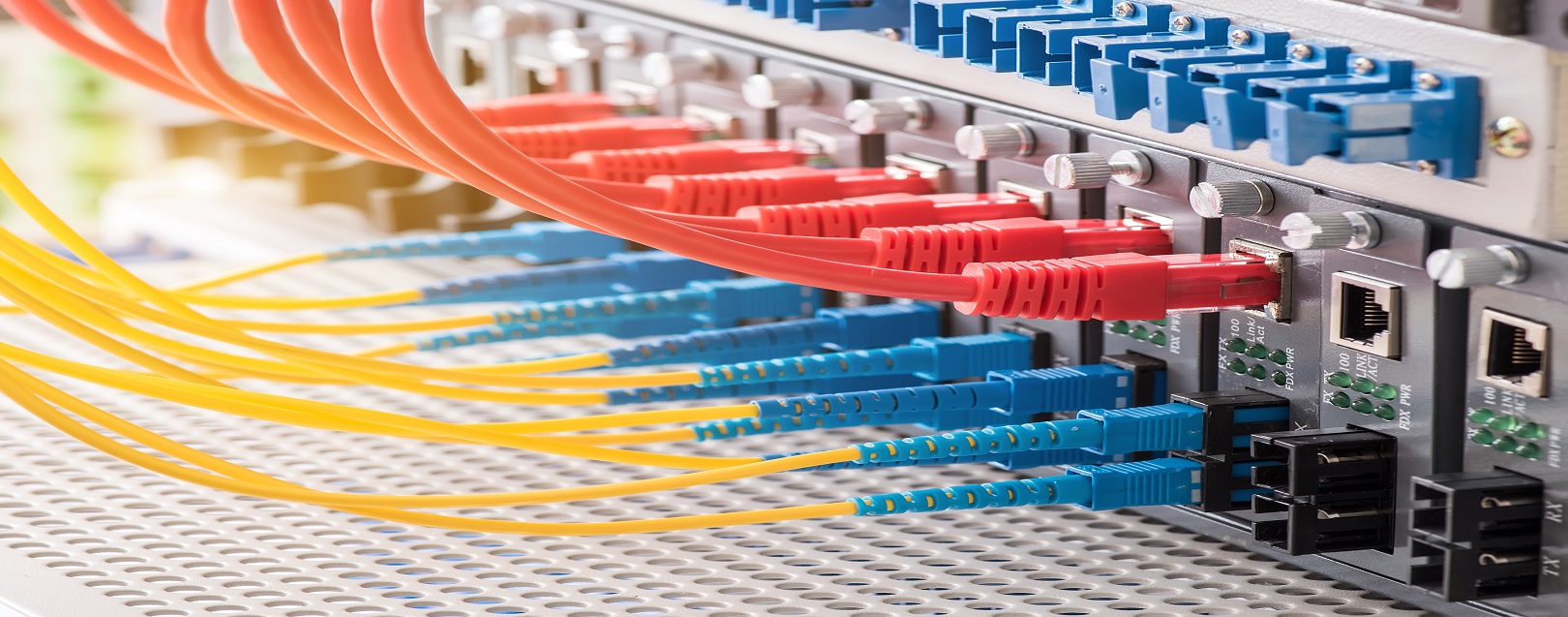

Do you remember how excruciating it was to stream something online a decade ago? Well, in those days, most Internet providers were using standard copper wires that were incapable of supporting data rates that were required for streaming. In fact, we spent more time buffering than browsing. But gone are those days, and today we are able to consume high-definition videos on our connected devices, all thanks to the usage of optic fibre cables (OFC).

While, to laymen, it’s still an ‘Internet cable/wire’, OFC is very different from the standard copper cable. OFC contains hair-like thin fibres that are made of silica glass and is designed for durability and speed that is the hallmark of the present day telecommunication and data networks. Today, OFC is the life blood that supports half the world’s communication networks. In India, the traditional copper wires started being replaced by OFC in the mid-2000s and today India has emerged as one of the largest users of OFCs in the world.

HIGH POTENTIAL

What is more interesting is that India, despite its huge domestic appetite, is also a major exporter of OFC. In FY2017 India’s total exports of OFC was $232.59 million, which makes it the third-largest exporter of OFC in the world, behind US and Japan. In fact, since FY2012, India’s exports of OFC have grown 66.10%. Concurring to the growth, a report published by ReportsnReports reveals that in CY2015, the demand for OFC raw material across the globe increased to 11,017 metric tonne (MT), up by 21.6% from 2014. And guess what? The global demand is expected to increase further by 90.6% to 21,000 MT by CY2020. And, when it comes to India alone, TechSci Research released a report revealing that the Indian OFC market is expected to grow at a CAGR of over 13% between CY2016 and CY2020.

These estimates are not surprising as some of the biggest names in communication have shifted over to OFCs in a large way. Tata Communications, a Tata group company, has the world’s largest wholly-owned submarine fibre network – more than 500,000 km of subsea fibre, and over 210,000 km of terrestrial fibre that connects customers of Tata Communications across continents. Similarly, Reliance Communications too has set up a 1,40,000 km, pan-India, OFC network. Also, Indian manufacturers of OFCs, from Birla Furukuwa to Polycab wires, have undertaken major turnkey telecom projects involving laying of OFC across the globe. And as the globe gets more and more ‘connected’ the demand for OFC is only rising.

DESTINATION CHINA

While Indian OFC manufacturers have managed to create a global footprint, what is interesting to note is that India’s largest export destination for this product is China. China in fact contributes to 14% of our total OFC exports. While this may bring smile of satisfaction to your face that there is at least a category where we are a net exporter vis-à-vis China, this should not be a surprise as China is also the largest importer of OFC in the world. Other destinations for India’s OFC include US, Poland, Germany and Turkey – in that order.

So, what makes China an attractive market for OFC? Ashish Jain, President & Business Head (Telecom), Polycab Wires Pvt. Ltd. says, “Currently, there is huge demand from China because the country is working on 5G projects – valued at $170 billion – that requires 90,000 km of OFC. Fortunately, for us, because China doesn’t have the capacity to meet its domestic demand, and because of our high standards of quality and competitive prices we are their sourcing destination of choice."

ROOM FOR MORE

While India has made giant strides in the OFC segment, the industry believes that there is much more scope for export growth if it is given the right incentives and environment. Currently, exporters receive a 1% duty drawback and a 2% incentive under the Merchandise Exports from India Scheme (MEIS). R. K. Bhatnagar, Director General, Telecom Equipment and Services Export Promotion Council (TEPC) explains, “Telecom equipment industry is a part of the technology sector, and at present, we are dependent on imports for most of the telecom products. Under Foreign Trade Policy (FTP) 2009-2014 we were given a duty credit scrip of 5%, which was reduced to 2% in FTP 2015-2020. We have recommended for special consideration for higher benefits for the technology sector.” Recently TEPC, after thorough research, has recommended items under 13 HS codes, including OFC, be given 5% MEIS benefits. Bhatnagar says that if the government can lend this support, exports from the telecom sector, including OFC, can increase by over $3 billion in the next three years.

Another major issue for manufacturers and exporters of OFC is the Goods and Services Tax (GST) that was introduced on July 1, 2017. Tax under GST for OFC has been fixed at 18%, which means a large chunk of an exporter’s working capital will remain in government coffers till the time the refund is issued.

Parag Tyagi of Himnish Limited, a Ghaziabad-based exporter, says, “The business has been growing substantially over the last 10 years. But with the introduction of GST we are very worried. In fact, we are spending a lot of time analysing how GST will impact us and how we can minimise it.” But then, there are exporters like Jain who have welcomed GST with open arms. “This is a positive move and will benefit the industry, because now we will be able to get input tax credit for all taxes paid,” says Jain.

DOUBLE BONANZA

Despite the low rates of incentives and the teething troubles that exporters face due to implementation of GST, the times are good for manufacturers of optical fibre cables. For those OFC manufacturers who have been able to backward integrate and produce raw fibre the opportunities are enormous, both in the country and beyond. For instance, in 2011, the Indian government created a project called National Optical Fibre Network, to be executed by India’s most prominent public sector undertakings (PSUs) – RailTel, Bharat Sanchar Nigam Limited and Power Grid Corporation to provide Internet to 2,50,000 gram panchayats by 2018. This project itself is enough to keep manufacturers posting satisfactory growth. In fact, in many cases the domestic market offers better margins! But then, exports offer more than just margins. Jain says, “Besides your company’s profit, exports offer you brand recognition globally. It’s a sense of pride to earn foreign exchange for India. But, I must add that 60-70% of our production is for the domestic market, while the remaining is being exported.”

ON HIGH FREQUENCY

While the sector is still in its nascent stage in India, the future looks very promising. However, currently, the market remains tilted in favour of larger manufacturer-exporters -exporters. According to exporters, they are happy with their current market share, but there is threat from US and Japanese companies who are ramping up capacities. In addition, countries such as Germany, Hong Kong, Denmark and Netherlands are fast catching up.

But, despite the competition, as India and the rest of the world make a push towards digitisation and more systems and companies make a shift to OFCs, the demand for OFCs is expected to continue grow even further. Aggarwal shares, “It’s a very promising time for the industry. The domestic demand is booming and new export markets are opening as OFCs are like the blood vessels for data communication.” Interestingly, India fulfils most of the OFC demands from countries like Bangladesh, Nepal and Africa. In fact, Indian-based original equipment manufacturers (OEMs) cater to almost 80% requirement of Nepal and Bangladesh. What is more is that established exporters can reap a healthy 8-10% margin.

With connectivity becoming as important as oxygen, the demand for OFC will only go up from here. Question is: Will Indian exporters be able to keep up the tempo? They can, we think!

.jpg)

Parth Aggarwal DIRECTOR, PARAMOUNT WIRES AND CABLES LTD.

TDB: Exports of optical fibre cables (OFC) has grown 66.1% since FY2012. What’s driving the growth?

Parth Aggarwal (PA): Several factors have contributed to this incredible growth. But, mostly it is the increasing demand for higher and faster connectivity across the globe that has been boosting its exports. Presently, there are several telecom projects under execution in countries like Bangladesh, Nepal, China, Sri Lanka, Africa, etc., and India-based original equipment manufacturers (OEMs) cater to almost 80% of the requirement in Nepal and Bangladesh.

Buyers that majorly procure optical fibre cable (OFC) from India include telecom industries, large infrastructure contractors and large retail based distributors that cater to Internet service providers, multiple system operators and civil contractors. Our company’s OFCs range from 1F to 144F, both armoured and unarmoured. And, several customisations go into the making of OFC, depending on the project requirement or the type of application it is used for.

TDB: How stiff is the competition amongst domestic suppliers?

PA: Suppliers mostly compete against each other in two ways: either by offering better quality or by offering lower price. Several OEMs have the advantage of backward integration and, at the moment, there is a huge deficit of fibre in the market. So, the few OEMs that can manufacture bare fibre use their resources strategically. Additionally, some companies (including ours) also offer services including laying, execution of turnkey projects, etc. Hence, many customers prefer companies that can provide endto-end solutions.

TDB: Are you saying that the business is restricted to mostly larger players?

PA: Yes, that’s somewhat true. The major reason being, producing bare fibre is a big challenge. To do the same, a company needs the financial strength and the infrastructure to manufacture bulk quantities as well as meticulous resource management and planning.

TDB: India is ranked third in exports of OFC. How can we improve on this?

PA: As of now, there is so much of demand for OFC from India that business will sustain for at least another decade. But, the leading manufacturers will have to prioritise their supplies and arrange their resources, mainly fibre, according to the changing demand. At present, export figures are directly related to availability of fibre to Indian manufacturers. So, the sooner availability increase, the faster exports figures will rise.

TDB: What are your views on the future of the OFC manufacturing sector?

PA: It’s a very promising time for the OFC industry because domestic demand is booming and new export markets are emerging. And, since the world is moving towards digitalisation, the demand is bound to remain stable in near term.

Rakesh Kumar Bhatnagar DIRECTOR GENERAL,

TELECOM EQUIPMENT & SERVICES EXPORT PROMOTION COUNCIL (TEPC)

TDB: Exports of OFC is rapidly growing from India. Where are our markets?

Rakesh Kumar Bhatnagar (RKB): Our product quality and timely delivery have won the trust of many overseas buyers. Today, India exports to over 100 countries – in fact, most major exporters have their presence in 30-50 countries. Going forward, the end-to-end, project-based approach suggested by TEPC, combined with credit support by Indian government, should help in achieving new and higher levels of exports to ASEAN and African markets. In fact, these are the markets that are yet to reach saturation – these markets are currently focussing on building broadband infrastructure to support their digital dreams.

TDB: Despite rapid growth, India ranks third in OFC exports. What is stopping us from reaching the top position?

RKB: Competition from other foreign players who have the backing of longterm credit lines is an area of concern. Credit lines in Japan, Korea and China are far better than India. Even within our domestic boundaries, limited incentives, unfavourable GST rates, absence of Made in India and PMA policies for infrastructure projects etc., are hindering growth. But, with that said, OFC manufacturers, because of efforts from TEPC would be now able to participate in trade fairs, which will give them an opportunity to showcase their capabilities and network with global buyers.

TDB: How helpful is the 2% reward under MEIS and 1% duty drawback?

RKB: Telecom equipment are a part of the technology sector. At present, we are dependent on imports for most of the telecom products. We have recommended for a special consideration for this sector. Prior to the Foreign Trade Policy 2015-2020, telecom products were given 5% duty scrip benefits, which has now been reduced to 2%. TEPC, after a thorough research, has recommended 13 HS Codes, including OFC, where India has the capability to export and have urged for a 5% MEIS benefit on the same. We estimate that the suggested 5% incentive, combined with other government export promotion schemes, can result in additional exports of over $3 billion from the sector in the next three years.

TDB: How does TEPC foresees the future of OFC manufacturing industry?

RKB: In the domestic market, demand is driven by factors such as growth of fixed broadband, replacement of BSNL’s ageing copper network by fibre optic cables, wireless backhaul network upgradation, increased penetration in rural areas and the need for higher speeds by 3G/4G networks. When it comes to exports, a credit line of $1 billion is already available to promote projects that support connectivity between ASEAN and India. This can translate into exports of over Rs.5,000 crore if Indian OFC manufacturers tap its full potential. So, the future definitely looks bright.

Get the latest resources, news and more...

By clicking "sign up" you agree to receive emails from The Dollar Business and accept our web terms of use and privacy and cookie policy.

Copyright @2024 The Dollar Business. All rights reserved.

Your Cookie Controls: This site uses cookies to improve user experience, and may offer tailored advertising and enable social media sharing. Wherever needed by applicable law, we will obtain your consent before we place any cookies on your device that are not strictly necessary for the functioning of our website. By clicking "Accept All Cookies", you agree to our use of cookies and acknowledge that you have read this website's updated Terms & Conditions, Disclaimer, Privacy and other policies, and agree to all of them.